Just How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre production processes represents a substantial development in top quality control methodologies. By supplying real-time, accurate dimensions of Fibre diameters, this technology resolves the vital demand for consistency in production requirements.

Significance of Fibre Diameter Measurement

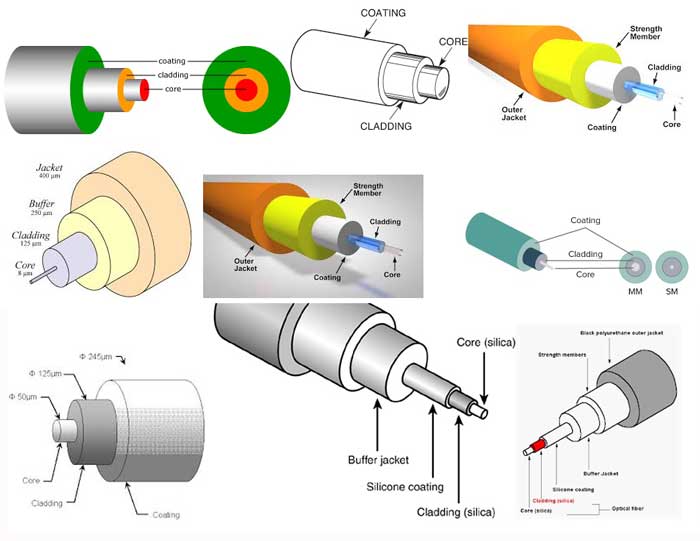

Precise dimension of Fibre Diameter is essential in the area of optical Fibre technology, as it directly affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter guarantees that the optical residential properties are preserved within specified tolerances, which is vital for optimal signal honesty.

Variants in Fibre Diameter can lead to raised losses as a result of spreading and modal dispersion, impacting the top quality of information transmission. In high-speed communication systems, such discrepancies can result in substantial deterioration of signal high quality, resulting in data mistakes and minimized performance. Constant Fibre Diameter is important for compatibility with connectors and splicing modern technologies, which are indispensable parts of Fibre optic networks.

Quality assurance procedures in Fibre production heavily depend on precise Diameter measurements to ensure conformity with industry criteria. By executing durable measurement strategies, makers can enhance item reliability, lessen waste, and improve general system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it offers as a foundation in the advancement of optical Fibre modern technology and its applications in contemporary interaction networks.

How the Analyser Works

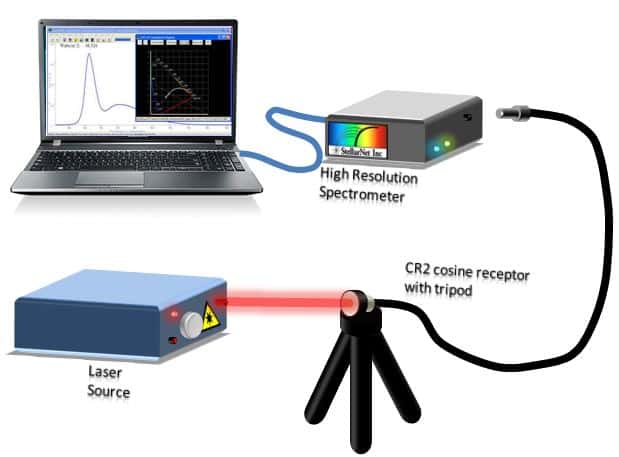

The reliable measurement of Fibre Diameter depends on sophisticated logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced photo handling algorithms to precisely analyze the Diameter of fibres as they are created

Originally, a laser beam is guided at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this darkness using high-resolution electronic cameras positioned tactically along the manufacturing line. The captured pictures are then refined in real-time to identify the Fibre's Diameter with outstanding precision.

The system utilizes advanced formulas that make up numerous factors, consisting of variants in light strength and ecological problems, to enhance measurement dependability. It can identify minute changes in Diameter, such as changes that could take place throughout the production procedure.

Additionally, the analyser is qualified of handling multiple fibers at the same time, increasing throughput without compromising precision. By giving rapid responses on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in keeping rigorous quality assurance criteria, making sure that the end product meets industry requirements and client requirements.

Benefits of Real-Time Surveillance

While standard techniques of keeping track of Fibre Diameter frequently involve taxing post-production checks, real-time tracking substantially improves the efficiency and top quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive approach allows producers to identify deviations in Fibre Diameter as they take place, instead of waiting till production is full to examine quality

By continuously measuring the Diameter throughout production, suppliers can guarantee that the fibers meet rigorous specifications, bring about decreased irregularity and improved uniformity. Real-time monitoring likewise makes it possible for immediate rehabilitative actions to be taken, reducing waste and preventing faulty fibers from entering the supply chain.

Moreover, this modern technology helps with boosted data collection and analysis, giving insights right into manufacturing trends and prospective locations for improvement. Such data-driven decision-making equips suppliers to optimize processes and keep high standards of quality assurance.

Additionally, real-time tracking cultivates a culture of constant renovation within the production environment. Workers are a lot more involved when they can see the impact of their work in real-time, important link causing enhanced accountability and a commitment to excellence. Generally, the execution of real-time monitoring systems in optical Fibre production equates to premium item top quality and increased customer complete satisfaction.

Effect on Manufacturing Efficiency

Executing optical Fibre Diameter analysers substantially improves manufacturing effectiveness by streamlining the manufacturing process. These tools facilitate continuous tracking of Fibre Diameter, allowing suppliers to find deviations in real-time. By identifying incongruities immediately, assembly line can be changed swiftly, reducing downtime and minimizing the chance of generating defective products.

Furthermore, the integration of these analysers right into the manufacturing operations allows far better source allowance. With precise Diameter measurements, drivers can maximize product usage, guaranteeing that resources are not squandered on problematic fibres. This precision also adds to much less scrap and rework, ultimately lowering manufacturing prices.

The automation supplied by optical Fibre Diameter analysers minimizes reliance on manual inspections, which are frequently time-consuming and vulnerable to human mistake. Consequently, employees can concentrate on even more critical jobs, enhancing general productivity.

In addition, the data created from these analysers can educate process renovations and help with much better decision-making. By analyzing fads in Fibre Diameter variations, makers can carry out proactive actions to boost manufacturing strategies and maintain constant high quality. In recap, optical Fibre Diameter analysers play a crucial function in improving manufacturing performance, leading to higher quality outcome and boosted success.

Situation Researches and Success Stories

Across various industries, study highlight the transformative effect of optical Fibre Diameter analysers on manufacturing processes. One popular instance is a leading telecommunications company that encountered challenges with irregular Fibre sizes, causing increased denial prices. By integrating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre dimensions, resulting in a 30% decrease in issues and substantial cost savings.

In addition, a study establishment focusing on sophisticated materials utilized optical Fibre Diameter analysers to improve their experimental processes. The analyser's capability to offer in-depth understandings into Fibre uniformity made it possible for the development of cutting-edge materials with enhanced performance attributes.

These success tales emphasize the essential duty of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing performance, and driving advancement across varied industries.

Conclusion

In verdict, the Optical Fibre Diameter Analyser plays a crucial duty in enhancing top quality control within Fibre production. As demonstrated through various instance researches, the my blog analyser verifies crucial for achieving like it exceptional product quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for stringent top quality control, making certain that the created fibers fulfilled exacting sector requirements.In final thought, the Optical Fibre Diameter Analyser plays an essential duty in boosting quality control within Fibre manufacturing.